Tracking and Tracing Construction Assets with the Location History API

)

TomTom’s Location History API enables us to safely store and retrieve the locations and movements of tracked devices. As developers, there are a plethora of ways we could use the Location History API (primarily the Objects Service and the Position History Service) to build applications that solve real construction industry problems. We'll examine some of the challenges in the construction field and how the Location History API can help solve them.

Construction is an asset-heavy industry. Equipment varies wildly in make and model — some equipment is easy to monitor using existing Internet of things (IoT) sensors and data dashboards. But other equipment — including legacy equipment — comes without connectivity, making it difficult to track. Replacing such equipment is expensive, but fortunately, there’s another solution.

TomTom’s Location History API enables us to safely store and retrieve the locations and movements of tracked devices. As developers, there are a plethora of ways we could use the Location History API (primarily the Objects Service and the Position History Service) to build applications that solve real construction industry problems.

Let’s examine some of the challenges in the construction field and how the Location History API can help solve them.

Efficient Resource Allocation

Equipment tracking provides a real-time awareness of when and where equipment is used. This helps with time management and enables constructions sites to solve the problem of staff standing around waiting for equipment to be free. We can reallocate equipment that is sitting idle for use at another work site and ensure that all equipment we could use for a job is being used to complete a job.

Further, having an accurate record of how much time a piece of equipment is used on-site can help with budgeting decisions. Records can ensure that companies do not rent equipment longer than necessary and identify scenarios where more equipment is needed. Greater use at a specific site may mean an outright purchase is cheaper than hiring. Site managers can then factor these costs into budgets for similar projects in the future.

Asset tracking is also essential for companies that hire out equipment, as underutilized equipment means missed revenue opportunities. It also provides a record of each equipment delivery to ensure that all hires are accounted for and also ensures that equipment is not sent to the wrong site.

Loss Prevention

Asset tracking can prevent the theft of high-value construction equipment. The more valuable the item, the more desirable it is to thieves. While insurance may cover a replacement, the process of filing a claim may be time-consuming and may risk increases in insurance premiums. Renting replacement equipment is an added expense. Equipment theft can also mean reduced productivity and completion delays. In some instances, delays can lead to missed deadlines resulting in hefty penalties.

Some sites employ security staff, but it is expensive and difficult to monitor all equipment at all times, especially on giant jobs or across multiple sites.

Vehicles carrying expensive assets such as raw materials benefit from location tracking. Suppose location history shows an expensive steel beam has been moving down the Pennsylvania Turnpike at 55 MPH when it is supposed to be on a construction site in Manhattan. In that case, you know you have a problem, and can work with authorities to recover your property.

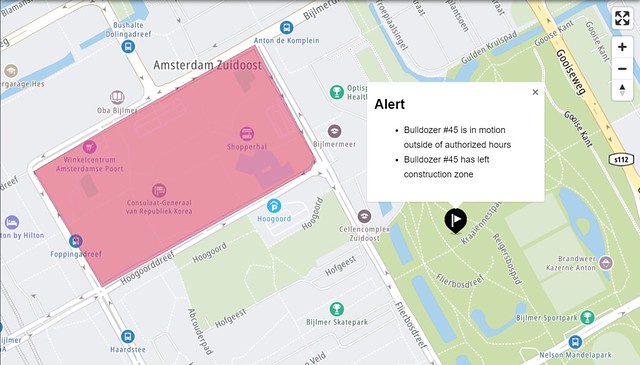

Location history tracking can help ensure that heavy machinery and expensive tools are where they’re supposed to be and aren’t being taken elsewhere without authorization. If a theft does occur, location history can aid in recovering stolen items. Developers can use Geofencing and GPS asset tracking to trigger a notification when equipment is operated out of hours or moved from a specific geofenced area. Bread crumb tracking can help authorities locate the stolen items quickly.

TomTom’s Location History service can manage and keep track of the locations of many objects. It can provide TomTom’s Geofencing service with a history of object transitions through fence borders.

Imagine a pile of lumber or steel careening down the road thanks to a thief who broke into a site. TomTom’s GPS tracking can tag these heavy materials. The fleet manager can then use a corresponding app to track the materials in real-time. It can prevent injury to those on the road near the heavy load and help police return the materials to their rightful owner.

Similarly, you can set up an alert using the TomTom Objects Service and Geofencing API for drivable machinery. This could be used to identify when equipment such as trucks, bulldozers, and cranes are accessed after hours or moved beyond a geofenced area at any time, which may indicate unauthorized use:

Asset Tracking to Aid Forecasting and Planning

We can also use location tracking to plan future work. The location history of construction assets helps us understand which ones might be needed to complete similar jobs in the future — how many of each equipment type workers used, how long workers needed them, and so on.

An example is the use of TomTom’s Location History API to track the amount of time spent moving equipment across different sites (or between companies and sites) by monitoring the moving vehicle’s hours of activity. An hour on the road each day moving can add up to over 20 hours a month. That is a staggering 240 hours annually or 30 days a year where equipment (and the paid member of staff driving) are tied up commuting. Awareness and actionable data can help increase worker efficiency.

Even better, we can improve travel time by combining travel time tracking with the TomTom Traffic API. We can use this to map the travel route and reduce travel time by getting real-time data on road conditions, jams, and live incidents.

With TomTom, we can put out fires before they occur. This means we can save the company thousands of dollars a day using TomTom asset tracking to get real-time data about how the staff uses the equipment.

Next Steps

Construction is just one of many industries benefitting from digital transformation. Asset tracking reduces theft, saves companies time and money by reducing site inefficiencies, and ensures that site managers can maximize the use of valuable equipment and optimize specialist staff’s time. Developers can create web and mobile asset tracking apps. These can provide real-time and historical data. This means companies can not only track their progress by effectively forecasting future materials and equipment needs, and they can stay competitive in future tender bids and increase company profits.

Want to learn more about integrating TomTom’s APIs in construction applications? Sign up for a TomTom developer account today.

To learn more about asset tracking, check out these related pages:

Tracking Product Page – learn more about the Geofencing API, Location History API, and Notifications API

Asset and Vehicle Tracking use case page – see a live demo and explore tutorials

Article: What is Fleet Tracking?

Article: How Location APIs can help power Fleet Management Software